usp compressed gas air system testing|Requirements for compressed Air in the Pharmaceutical Industry : Big box store Pharmaceutical gas analysis, compressed air testing, oxygen purity testing, nitrogen testing, carbon dioxide testing, GMP compliance, SGS Life Science Services, pharmaceutical production, gas contamination testing, microbiological analysis, pharmacopoeia standards Created Date: 5/8/2023 9:39:55 AM

web1 de dez. de 2023 · Changes Made to Rule 33 After Publication (“GAP Report”). The Advisory Committee changed the proposed amendment to require that any motions for new trials based upon newly discovered evidence must be filed within three years, instead of two years, from the date of the verdict.

{plog:ftitle_list}

Resultado da Explore the filmography of Jessa Rhodes on Rotten Tomatoes! Discover ratings, reviews, and more. Click for details!

The USP (the US Pharmacopoeia) handle the testing of water or oil content quite easily: the so-called mirror test is required. In this case, one lets the gas flow against a .

INTRODUCTION. 16 This guidance is intended to assist manufacturers of medical gases in complying with applicable. 17 current good manufacturing practice (CGMP) regulations (21 . Gases and air coming into contact with a pharmaceutical product must be of an appropriate chemical, particulate, and microbial quality. Compressed air sampling should be a key part of an environmental . Each of the types of potential air quality issues has different underlying causes and testing methods. In general, compressed air testing is governed by ISO 8573. Depending on the application, additional standards .Microbial Testing of Compressed Air Micro Testing of Compressed Air or Bioburden Testing per ISO 8573-7 is generally conducted by the pharmaceutical, medical device and food industries. Microbial contaminants found in the compressor or compressed air lines can be devastating to a final product in these industries. A regular Micro Testing program can provide insight to a .

Pharmaceutical gas analysis, compressed air testing, oxygen purity testing, nitrogen testing, carbon dioxide testing, GMP compliance, SGS Life Science Services, pharmaceutical production, gas contamination testing, microbiological analysis, pharmacopoeia standards Created Date: 5/8/2023 9:39:55 AMcompressed air. The standard consists of nine separate parts, with part 1 specifying the quality requirements of the compressed air4 and parts 2 – 9 specifying the methods of testing for a range of contaminants. The test method for microbial monitoring of compressed gases is provided in ISO 8573-75.Compressed Breathing Air Testing. Commercial & Sport Dive; NFPA 1989 / Fire; . specifications like USP will dictate what percentage of other gases is acceptable in a 99% nitrogen gas. . and microorganisms are so abundant in the ambient air, it is quite possible for them to find their way into a compressed gas system. Leaks, maintenance .

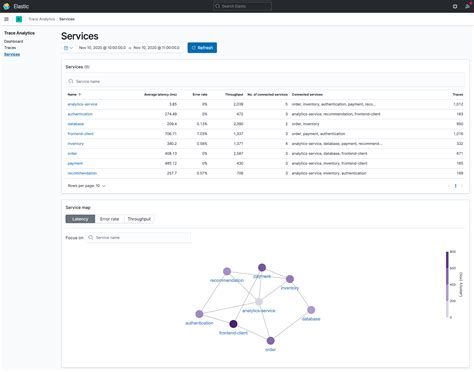

Trace Analytics

Validation of Compressed Air Systems in the Pharmaceutical Industry. The validation of a Compressed Air System in the pharmaceutical industry is typically performed according to the requirements and guidelines provided by regulatory authorities such as the International Society for Pharmaceutical Engineering (ISPE) and the United States Pharmacopeia (USP). Specifications like USP dictate acceptable amounts of other gases present. Gas purity can be influenced or disrupted by leaks in the system, which can add ambient air to the mixture. . Pure gas testing can help users meet standards like JECFA, FCC, CGA, EU 231, NFPA 99, USP, ISO 8573 and more. . To read articles on Compressed Air and .A 24-48 hour incubation period will then determine the presence, or otherwise, of any viable micro-organisms within the air system. d) Remaining test with gas detector tube : Compressed air, oxygen, nitrogen, and carbon dioxide are often used in pharmaceutical production environments and are subject to the Good Manufacturing Practices. Compressed air systems are a critical component of many pharmaceutical manufacturing facilities. With any new system creation, addition, or change, a validation should be performed to ensure the compressed air is of appropriate quality for its intended use. . USP, ISPE, or CGA). Particles can be analyzed in a variety of ways. Some .

(1) Once per quarter for compressed air and nitrogen gas.- In Parenteral Dept. (2) Once per quarter for Compressed air – In Solid Dosage Area. 5.8 Sample quantity: Adjust the flow meter to 6 m3/hr & draw the sample for 10 min to sampled 1 m3 of air or nitrogen gas. 5.9 Sampling Point: Compressed Air & Nitrogen Gas in Parenteral Department.

TRI Air Testing pharmaceutical services for compressed air and pure gas testing includes Direct Product Contact, Indirect Product Contact, United States Pharmacopeia (USP), European Pharmacopoeia, ISO 8573, ISO 14664 compressed air standard. . ambient air and pure gas delivery systems. This includes a multitude of pure gas types up to Five 9 . 3.1 Sterilise the air sampling flask together with 100 ml SCDM, silicone tube for inlet & outlet. 3.2 Take the assembly to the sampling area and sanitize the sampling site with 70% IPA. 3.3 Open valve of the compressed air system for five minutes and allow air to pass out. 5.3 Test for Oil and Moisture Content Note: These tests are applicable for Compressed air points only. 5.3.1 This test shall be performed by the external testing laboratory as per protocol or by using gas detector tubes (Gastec). 5.3.2 Frequency Sample Point from Compressed Air Generation System: Once a MonthAt CEGTH, we offer effective testing solutions for your compressed air systems as per the guidelines of ISO: 8573/ USP/EP/BP. Breathing Air Validation. The Compressed Gas Association sets quality standards for breathing air is GRADE D (ANSI/CGA G-7.1’97) CEGTH offers testing of breathing air quality for the following parameters:

Using our A2LA Accredited Laboratory for your analytical needs assures you that our laboratory staff, test equipment and methods, quality assurance of test and calibration data have met or exceeded internationally accepted standards . Oxygen USP, medical air USP, and CMG mixtures are used in hyperbaric chambers. Nitrogen NF is used to operate power tools during patient care procedures. CMGs are typically supplied to a medical gas piped .Assay— Determine the oxygen concentration of Medical Air using an electrochemical cell analyzer readable to 0.1% of oxygen and calibrated with ambient air to an accuracy of ± 0.2% of oxygen. [NOTE— The instrument utilizes the variations of electric current produced by the interaction of oxygen with an electrochemical cell to display the oxygen strength of a confined .

According to the Compressed Air and Gas Institute (CAGI) and the International Organization for Standardization (ISO), the three major contaminants in compressed air are solid particles, water, and oil. CAGI promotes proper use of air compressors with various educational tools, while ISO 8573 is directed at the very specific areas of compressed air purity and test .A compressor compressing oil-free does not allow any additional oil to enter the compressed air system. But oil aerosols are already contained in the intake air or can enter the compressed gas system through other components, the compressed air still has to be treated. 80-00012-whitepaper_pharma_int.indd 11 01.04.19 17:53 Common uses of compressed air The ISPE Good Practice Guide asserts that a logical method for determining the requirements of a facility’s compressed air quality is to review the role of the gas in the process. Process gases and compressed air are used in a variety of ways depending on the product manufactured. While some facilities use compressed air in .

Moisture:– All atmospheric air contains some water vapor which will begin to condense into liquid water in the compressed air or gas system when the air or gas cools past the saturation point, i.e., the point where it can hold no more water vapor. The condensed moisture must be removed by a separator and trap.Trace’s AirCheck Kit™ K811 is designed to obtain samples from points of use. Sampling includes Particles, Water, Oil Aerosol and Vapor, and optional gases. ISO 8573-1 is one of the few standards available for non-breathing air that addresses a wide variety of manufacturing needs.USP Oxygen 99 Percent-2004: N/A: 10: N/A: 300: N/A: N/A: 99.0-100.0: . We’ve been testing compressed air and gases for over 30 yers. . and modifications of compressed air and gas systems should all be validated prior to use. Air or gas system validations become even more critical in the cases of pharmaceutical or food manufacturing .

Quantus provides compressed gas testing for Life Sciences, including oil mist and vapor analysis. Ensuring safety, compliance, and optimal performance. . Ensure the highest standards of purity and compliance in your compressed air and gas systems with Quantus. Our expert testing services are designed to meet the rigorous demands of FDA .Restricted-Access Barrier Systems (RABS), and isolators consists of clearly . Compressed gases such as air, . (FDA aseptic filling guide ) Confidential and proprietary. ISO – 8573. Part 1: Contaminants and purity classes. Part 2: Test methods for aerosol oil content. Part 3: Test methods for measurement of humidity. Part 4: Test methods .Air Trace® compressed gases model. The test method requires that: All equipment is sterilized prior to use. Connect the sample inlet to the compressed gas line, including any electrical control connections to the instrument. Perform a blank of the gas in test, this allows a purge cycle of gas to be tested to clear out any

In most cases, end users select compressed air system components by comparing technical data from various air treatment manufactures. In 1991, the International Standards Organization (ISO) established the 8573 compressed air quality standard to facilitate compressed air system component selection, design and measurement.

Requirements for compressed Air in the Pharmaceutical Industry

Pharmaceutical Compressed Air and Compressed

900 laboratory toc analyzer

WEBMyFreeMP3是一款由大佬 刘明野 开发的免费 在线音乐播放器 ,简单理解就是版的播放器,没有客户端。. 但是上面可以搜索到的歌曲都是可以在线免费试听,也有不少歌单。. 不过因为某些原因,目前不支持腾讯、酷狗、酷我等产品的版权音乐。. 在MyFreeMP3除了 .

usp compressed gas air system testing|Requirements for compressed Air in the Pharmaceutical Industry